SCROLL DOWN

KISEKI PLANT FACTORY

Making the Earth and people healthy

with plant factory technology

SCROLL DOWN

KISEKI PLANT FACTORY

Making the Earth and people healthy

with plant factory technology

KISEKI PLANT FACTORY provides comprehensive solutions for plant factory businesses, from crop selection, factory design, installation equipment layout, operational planning, to employee training once the factory is complete.

Serves a wide range of needs, from multi-variety small-scale production to large-scale production of the same variety through unit cultivation.

Up to 6 times higher production per unit area by stacking cultivation units vertically, the production per unit area is maximized.

One device covers multi-variety small-scale production to single variety large-scale production.By connecting specialized cultivation units to the main unit responsible for control, a smooth transition from experimentation and validation to mass production can be achieved.

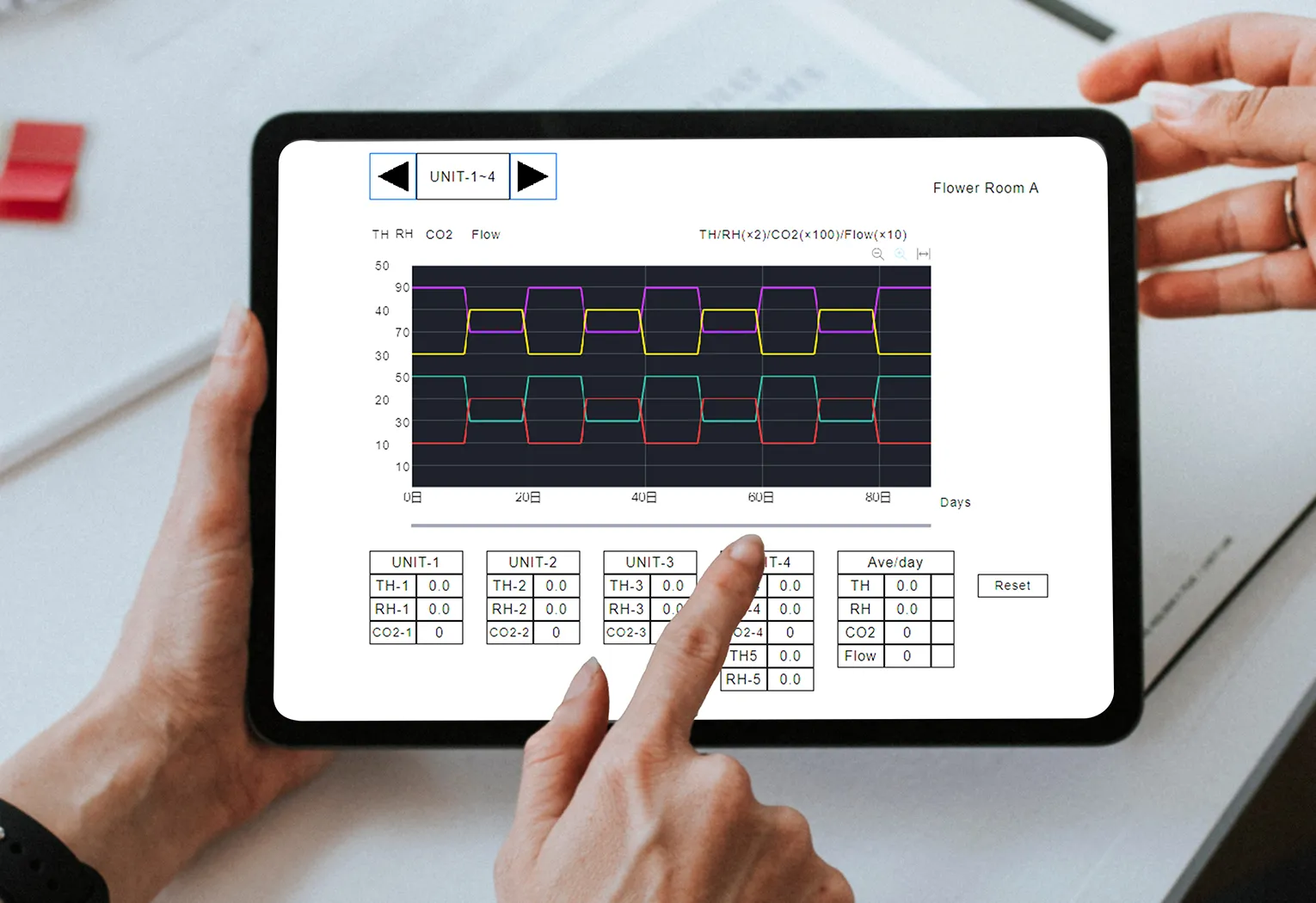

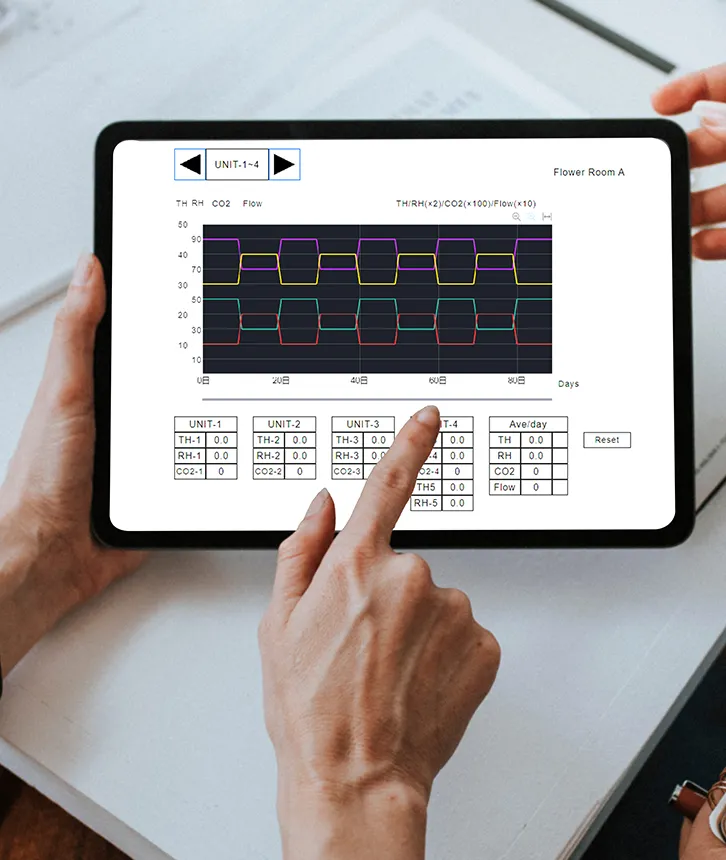

Automatically manage variables for cultivation such as temperature, airflow, lighting, nutrient solution, CO2, etc., to establish an optimal cultivation environment and consistent quality.

By connecting to the internet, real-time information of each UNIT can be acquired from remote locations, allowing for detailed monitoring and adjustments.

Water treatment equipment that supplies optimal water for plants.

Removes various mineral components and chlorine present in tap water, ensuring consistent cultivation regardless of water quality variations in different locations.

In areas where water is scarce, we practice environmentally friendly plant cultivation by reusing water.

Optimize fertilizer supply according to the growth status of cultivated plants.

The mixed fertilizer tank can blend 8 types of fertilizer solutions. By installing a maximum of 8 mixed fertilizer tanks, fertilizer variations can be expanded up to 64 combinations.

Combined with KISEKI GROW UNIT, high precision fertigation can be achieved. Linking the cultivation management system with the fertilizer supply equipment allows changing the supplied fertilizer on a daily basis.

Creating profit and loss simulations based on the infrastructure conditions of the planned construction area and the selling prices of the produced Plants. We conduct a hearing on the business image and provide optimal planning proposals based on its content.

After the contract, we will work together with partner companies to construct a suitable indoor cultivation factory using our various equipment and provide staff training to support proper operation.